This industry as used in this report includes establishments engaged in the manufacture of sash, doors, blinds, window frames, door frames, moldings, stair material, newels, mantels, store fixtures, and all kinds of builders’ trim or finish.

A large number of the establishments are comparatively small and confine their operations wholly to custom work. Many of them are operated in connection with a retail lumber business. Some are run by contractors who carry on large building operations, and manufacture trim, mostly for their own use. Some custom mills in the larger cities are quite extensive and employ a large number of workmen.

A few establishments manufacture for the general market. Such establishments, as a rule, employ a larger number of workmen than the custom mills or factories, have their work more systematized, and pay somewhat lower wages. The latter fact may be accounted for by the greater division of labor whereby an employee, while being expert in the operation of a particular machine or in performing certain work, is not a skilled workman generally, and so can not command as high wages as an all-round skilled mechanic.

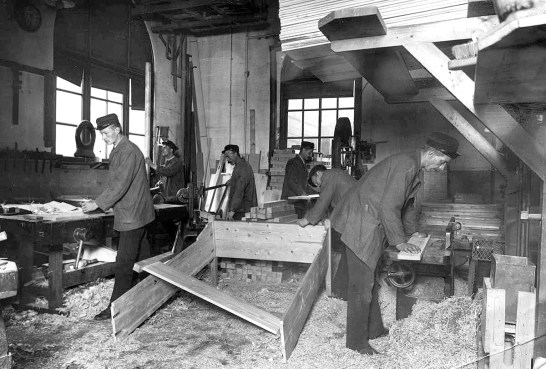

There is hardly such a thing as a typical factory in this industry in the sense that there is a typical sawmill or cotton factory. The work may be done on the second floor of a small building, the power being rented with the room; or the factory may consist of one or more large buildings with so much machinery that a considerable force of machinists will be regularly employed to keep the machines in order.

Neither is there any regular or established ratio between the number of employees in different occupations. One establishment may have an approximately equal number of bench men, machine woodworkers, and laborers; another will have three or four times as many bench men as machine men; and in another the proportion will be reversed, depending on the particular class of work the factory turns out.

The arrangement of the factory and machines will depend upon the class of work done, the space at the disposal of the management, and the latter’s ideas as to convenience and economy. The differences that are found are between establishments rather than between different sections of the country or different localities.

The work in these factories resolves itself into three general classes, bench work, common labor, and machine work, and the occupational terms used in this report are bench hands, laborers, and machine hands. A brief description of the terms used follows:

Bench Hands

The men engaged in this occupation are known also as benchmen, bench carpenters, shop carpenters, inside carpenters, and cabinetmakers. Most of the work is done at a bench, as distinguished from building or outside carpentering work. These employees make doors, sash, blinds, window frames, cabinets, etc., fitting and putting together the parts that have previously been prepared by machine hands.

They also shape and form such articles as can not be made by machines. In some shops work is done by hand that in other establishments is done by machinery. In some establishments men are employed who are able to work interchangeably at the bench and at the machines.

As with machine hands, carpenters or bench hands differ greatly in ability, some being able to do all kinds of difficult work, while others can do only the simpler kinds of work or, perhaps, only one or, at most, a few kinds. As a rule, the more skilled mechanics who can do all kinds of work are found in the smaller establishments.

Laborers

Those engaged in this occupation do a great many kinds of miscellaneous work about the factory, handling lumber, material, and finished product, and assisting other workmen, particularly machine hands. They bring material to the machines and take it away after it is worked, assemble parts that are to be put together, pack goods in storehouse or load on wagons or in cars for shipment, and do any other common or unskilled work about the factory or yard. The number of laborers as compared with the other employees is usually larger in establishments employing a large number of machine hands.

Machine Hands

By the use of various machines, employees in this occupation plane the lumber, saw it into lengths, widths, and shapes, mortise and tenon the parts of doors, sash, blinds, etc., make moldings, turn spindles, posts, and balusters, sandpaper, or smooth material or finished product, etc. A first-class machine hand is able to operate any of the machines usually found in a factory, and is supposed also to be able to keep his machines in order.

In the smaller establishments, and in the shops doing a high grade of work, the machine hands often, if not generally, actually use different machines, as the character of their work may require, one man doing all the machine work on a given piece of work. In larger establishments, when there is a greater division of labor, a man will be employed continually on one machine and may know nothing about the operation of any other. It has been found impracticable to separate these two classes of machine hands.

Wages and Hours of Labor in the Lumber, Millwork, and Furniture Industries, 1890 to 1912

Printed by The United States Bureau of Labor Statistics – August 14, 1913

-Jeff Burks