The following interesting story of a man’s reckless treatment of a machine illustrates, very forcibly, that it is more times the man’s fault than the machine’s that the latter refuses to work properly. Of course, it means the replacing of prematurely-aged machinery with new, to have them run under careless or incapable management; but even at that, we do not believe that there is a single machinery manufacturer who would like to see the product of his brain, or his brawn, abused for the sake of added profit. The story comes from a bright correspondent of the “Indianapolis Woodworker.”

Some years ago, I left the furniture factory, where I had been employed as a machine hand, to look after and keep in repair four small planers in a slack barrel cooper shop. It was with considerable pride and elation that I had accepted the position, which had been offered to me through the superintendent of the factory, who had been asked to recommend a man for the place, and, as I was but one out of nearly a hundred or more in the machine room, I felt real chesty to think that out of that bunch I was the lucky chap. It jarred me considerably, however, when the sanderman said, with a touch of sarcasm in his voice, ‘I guess you must be the only one whom the boss wants to get rid of.’

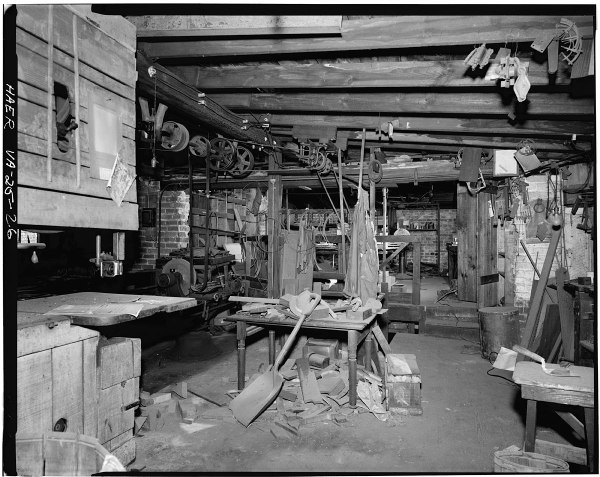

I did not let this dampen my spirits any, however, and the morning I was to take up my new duties, I was early at the shop taking a look around the machines I was to look after. A slovenly-looking fellow was pouring oil over the various bearings of one of the heading planers, and the machine certainly looked as if it never had a cleaning; it was covered with dirt and grease from one end to the other, and, as I watched the feeder slopping the oil around, sometimes managing to get it in the proper spot and again missing it altogether, I made up my mind that there would be a change made in the methods of oiling—provided I made good and kept the place.

When the foreman came and sized me up, I saw a slight smile of amusement pass over his face, as if he wondered where I had obtained the necessary gall to attempt a job of that kind. However, he treated me right and explained that three of the machines were out of commission and that they were unable to do anything with them. The whistle blew to commence work while we were talking, and I heard the shrill note of a slipping belt as the heading planer was started, and pretty soon, above the din of the other machines could be heard the thumping and pounding of that planer.

Filled with dismay, I turned half around, expecting to see the machine coming my way; but my fears subsided somewhat when I saw that the bolts were still holding it down, despite its frantic efforts to get away. Even as I looked at it, a light film of smoke began to rise from one of the cylinder boxes, and soon both bearings were smoking furiously, despite the fact that a sign, labeled ‘No Smoking,’ hung just beside the machine on the wall.

The foreman told me I was to have a free hand in placing the machine in order, also the others if I succeeded with the first one. I remarked that it seemed as though there was no time like the present to start in, and, after I had got inside of my jumper and overalls, I motioned to the feeder to stop the machine, which he did. I then had him run the belt off, and took hold of one of the cylinder pulleys, gave it an upward pull, and it came up nearly ⅛ inch.

Going around to the other side, found the bearing there had nearly as much play as the other. I then removed the caps of the bearings, and found that enough babbitt metal had carried over to fill all the oil grooves and had nearly filled the oil holes, so that scarcely any oil could work its way through. The babbitt metal was also very loose in both bearings, while the journals were badly cut. I decided that it would have to go to the machine shop and have the journals turned up, and any possible kinks taken out of it.

I took off the knives, and, judging by the weight of each that they were not of the same weight, started to look for a knife balance, to find that there was no such thing in the shop. The foreman laughed when I asked him, and said: ‘Good Lord! What do you want such a thing as that for? We never had any, and you are the first one who has ever asked for such a thing.’

He also informed me that the millwright ground all the knives. I asked him to show me where the knives were kept. He led the way to a work-bench near the engine, and, pulling out a box of knives from beneath it, showed an assortment from which it would puzzle anyone to find two of the same weight that would run together. They were all thickly coated with rust. Some were ground wide at one end and narrow at the other, some were hollow in the center, and others were full in the center and narrow at each end. I put my rule on them all, and no two were of the same width.

I told the foreman to have them ground so that both knives of each set would be uniform in width, as I would not use them in that condition. He did as I requested, but the millwright refused to grind them again, saying they were good enough, and no arguments had any effect until I brought a written order from the general manager, which straightened him out in a hurry, and he did as requested; but he let some of them get hot enough to blue them back about ¼ inch on the cutting edge.

There were several pairs of dull knives on hand, and these I took over with a hint that in case they were not properly ground, I would apply for another order from the office. This settled that difficulty, and I had no further trouble in that direction. I made a rough sort of knife balance, which answered the purpose very well, and corrected any difference in the weight of the knives.

As to the planer, I leveled the rolls and bed, and gave the machine a general overhauling, by which time I received the cylinder back from the machine shop. I got two short pieces of old shafting, heated them red-hot, and laid one in each bearing, from which I had removed the old metal, and placed the cap over it to get warm also.

I took some heavy wrapping paper and wrapped it once around the journal, bringing the lap to one side, where the liners would hold it down straight. Around this I wound some heavy twine, spirally, and in each direction. Next I cut some liners out of good, heavy cardboard, cutting several deep notches in one edge of each piece.

I then put new metal in a ladle, and put it over a slow fire to melt, while I placed two small blocks of even thickness on the bed of the planer. On these I placed the cylinder, after taking out the pieces of shafting. After adjusting so that the cylinder was in line, and high enough to allow sufficient metal beneath the journal, I placed my liners with the notched edge to the journal, put on the caps and screwed them down hard, then cut some washers out of cardboard to fit over journal at the end of each box, to keep the clay from crowding in between the journal and boxes, and which allowed the metal to come out flush with the ends of the boxes, and make a neat job when finished.

I then put on the clay, using great care to cover every opening that would possibly allow the babbitt to escape, leaving a small vent at each end of each bearing to allow the air to escape. When I poured the metal, which was just hot enough to brown a dry pine stick, I let it run from the ladle in a steady stream and as fast as I could, without letting it overflow before the bearing was completely filled.

The results were certainly pleasing, the bearings being as smooth as could be asked for, without any blowholes or other defects. After removing the paper from the journals. I placed the cylinder back in the boxes, without a bit of scraping, replaced the wide-notched liners with some plain ones ⅛ inch narrower, cut an oil channel in each cap and fitted each one with an oil cup, placed caps in position and adjusted them nicely, then put on a pair of sharp knives—and that machine was ready for business.

When everything was ready to go, the machine was started. The foreman came to watch how things would go. I was really nervous, fearing that possibly something had been overlooked and would cause trouble, this being the first occasion where I was compelled to rely on my own judgment entirely, having been more used to helping repair than in taking the lead myself.

The machine, which was speeded at 4,800 r.p.m., ran very smoothly, and, as it held together, my fears subsided, and I motioned the feeder to feed in some pieces, and, while they were passing through, I adjusted the pressure-bar. Then I threw the feed lever down to the last notch, the feed being a variable friction, and the way the headings went through that machine certainly wasn’t slow.

After watching things a while, the boss turned to me with a gratified smile and said: ‘By gosh! young fellow, I never would have believed you could do it; but that old trap (it was only about two years old) is doing as good work as when it was first installed.’

Realizing that it had only been a lack of proper care, and that the machines were not to blame, I started in to fix up the others along the same lines as the first, and in a short time I had the others going to the limit— and doing good work.

I held this place about a year, and then having a better position offered me, accepted it, and left the machines to the tender mercies of one of the feeders, who had acted as my helper in repair work, and being thought competent to do the work, was consequently appointed to fill the position. I received a letter from the foreman a year later, however, saying that the machines were then in as bad shape as ever.

The National Cooper’s Journal – March, 1906

—Jeff Burks